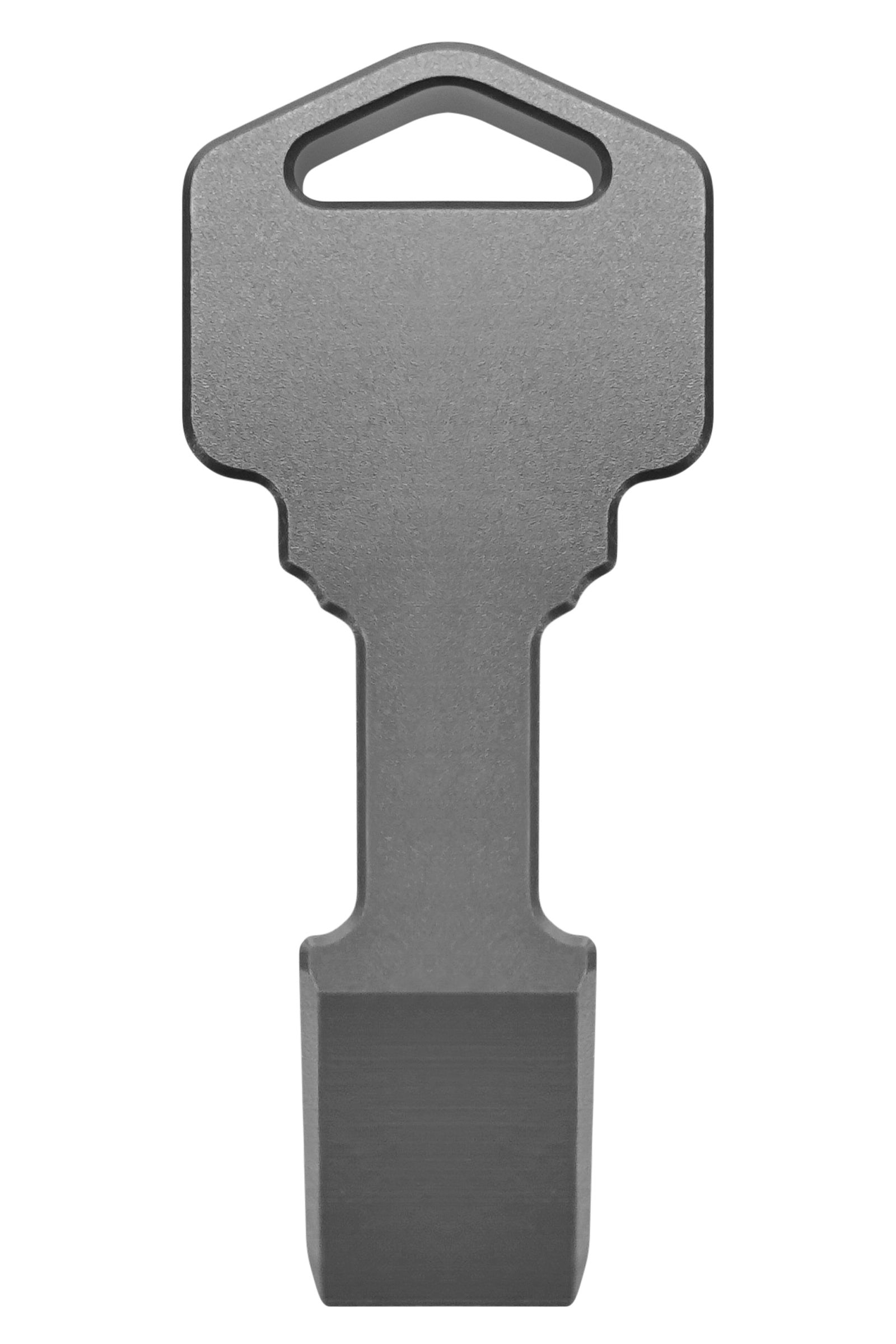

Keypry EDC Pry Bar

Keypry EDC Pry Bar

Couldn't load pickup availability

KeyPry EDC Pry Bar – Compact Strength, Always Within Reach

The KeyPry is our take on the perfect keychain pry bar: compact, rugged, and built for real daily use. CNC-machined from premium materials and thoughtfully designed for comfort, it's a tool that doesn’t just look good on your keyring — it delivers when you need it most.

Built to Be Ready. Every Day.

Ultra-Portable: At just 42mm long and 17g light, KeyPry is compact enough to carry every day without adding bulk.

Just 6mm thick, it slips easily into your pocket, backpack, or keychain loop.

Precision CNC Machined for maximum strength and long-term durability — this isn’t stamped sheet metal.

Made for Real Use – Not Just Looks

Unlike other “tactical” tools that look cool but don’t perform, KeyPry is designed to actually get the job done:

Open paint cans and stuck boxes

Scrape, clean, and pry

Use as a flat screwdriver in a pinch

Even split kindling when you're in the wild

Its sleek, contoured shape feels great in hand and looks even better on your kit.

Everyday Durable

Rust-resistant and wear-resistant, built to survive years of daily carry.

Designed to handle abuse — and come back for more.

No-Nonsense Lifetime Warranty

We stand behind KeyPry for life. No fine print. No weird conditions. If it fails, we’ll replace it. Simple as that.

Specifications

Weight: ~17 grams

Length: 42mm

Width: 18mm

Thickness: 6mm

Material: Solid billet, CNC-machined

Finish: Wear- and corrosion-resistant

Why KeyPry

Functional design that works — not just looks

Lightweight, strong, and built to last

Always on hand, never in the way

Guaranteed for life

Whether you’re cracking open a stuck lid, scraping gunk off a surface, or just want to be ready for anything, the KeyPry belongs in your pocket.

CRAFTING MODERN TOOLS THAT EMPOWER THE MODERN WARRIOR.

Gravity knives were originally designed as a practical tool, primarily for military purposes.

Developed during World War lI by German paratroopers, the unique sliding blade mechanism allowed soldiers to operate the knife with one hand, which was crucial if they needed to cut themselves free from parachute cords or other gear while using their other hand for stability or balance.

The gravity-operated sliding mechanism also allowed the knife to be deployed quickly and efficiently.

Unlike spring-loaded switchblades, which use a mechanical spring to push the blade out, gravity knives rely on the blade's weight and gravity to slide open.

This design was both simple and reliable in harsh conditions

This minimized the need for complex parts that could jam or break in the field. Over time, gravity knives became more widely available, though they remain a specialty tool with specific use cases, especially where one-handed operation is essential.

The Legacy of WW2 Rigger Pouches

Originally crafted by paratroopers and riggers in the field, these pouches were born out of necessity. Soldiers needed lightweight, durable, and versatile solutions to carry critical gear such as ammunition, tools, and personal items during combat. Using spare canvas, riggers fashioned pouches that could be easily attached to belts or harnesses, embodying resourcefulness and practicality. The Rigger Pouch honors this history by embracing the same principles of adaptability and durability.